Reducing the cost of storing corrosive products

If you are in the Automotive, Aerospace, Engineering or Electronics industry the chances are you have to store replacement parts – sometimes up to 15 years or longer.

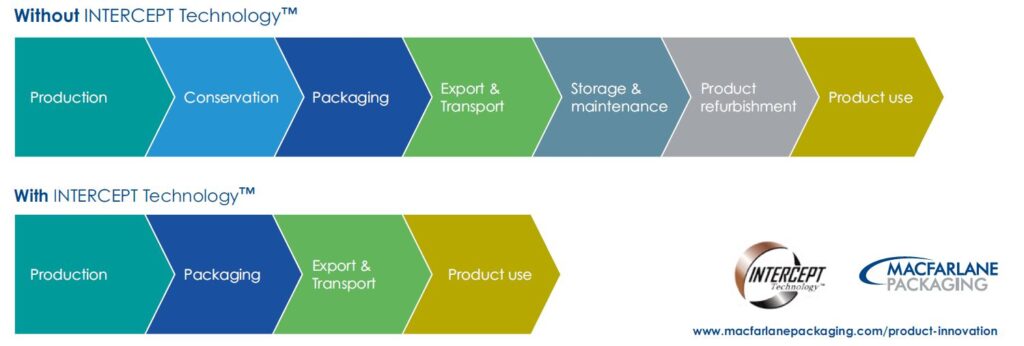

As many of the required parts are liable to corrode their storage can be process heavy – with lots of steps to ensure that these high value components will be fit to use when they are called upon to kick into action.

Processes can involve undertaking conservation before packaging, ensuring warehousing conditions are right for storage, regular inventory checks for quality purposes, refurbishing the product and then repackaging before distribution to the end user.

Some parts are also dipped in oil for their period of storage – these then need to be cleaned off before repacking.

All of these steps and processes incur costs, they add to the production cycle of a product and can be a drain on resources. This could be an area for significant savings – increasing your competitive edge and delivering operational efficiency.

There is a solution available that can guarantee the lifespan of your products for up to 15 years without repackaging.

Smart conservation and packaging solutions with INTERCEPT Technology™ provide corrosion protection even under extreme conditions.

These solutions offer secure protection during transportation and storage, negating the need to conserve or refurbish product. Storage becomes straight forward too – no maintenance required.

By avoiding unnecessary processes and reducing packaging materials, significant savings can be achieved.

If you would like to find out more about INTERCEPT Technology™ contact us today to find out we can revolutionise your storage of corrosive products: https://macfarlanepackaging.com/contact-intercept-technology/