3 quick-install packaging automation systems for ecommerce

The peak season for online shopping is fast approaching, and retailers are preparing to manage increased orders and demands.. If you are an internet r…

Auto strapping machines and friction welders can dramatically increase speed and throughput, all while lowering packaging and labour costs, giving you a rapid return on investment.

Implementing automatic strapping machines ensures your products are secured and protected effectively, allowing you to control and scale your packaging quality.

Using automatic strapping machines helps you control the amount of materials used to budnle products and secure pallets, minimising waste and creating a more sustainable packaging operation.

Our dedicated automation experts can seamlessly integrate strapping automation technology to augment your packing processes.

This is just a small range of the bag automation systems we can provide. If you can’t see what you’re looking for, contact us today to arrange an appointment with one of our automation experts. We can deliver tailor-made strapping and banding solutions for your operation.

An easy-to-use entry level friction welder for use with both polypropylene and polyester strapping.

Ideal for securing pallets, this ergonomic battery-operated strapping tool is portable and lightweight. It can be used for vertical and horizontal strapping and operated with just one hand. Tension force and sealing time are adjustable.

The iQ-400 is a semi-automatic strapping machine with dual tension mode. This allows for a wide variety of applications at the flick of a switch.

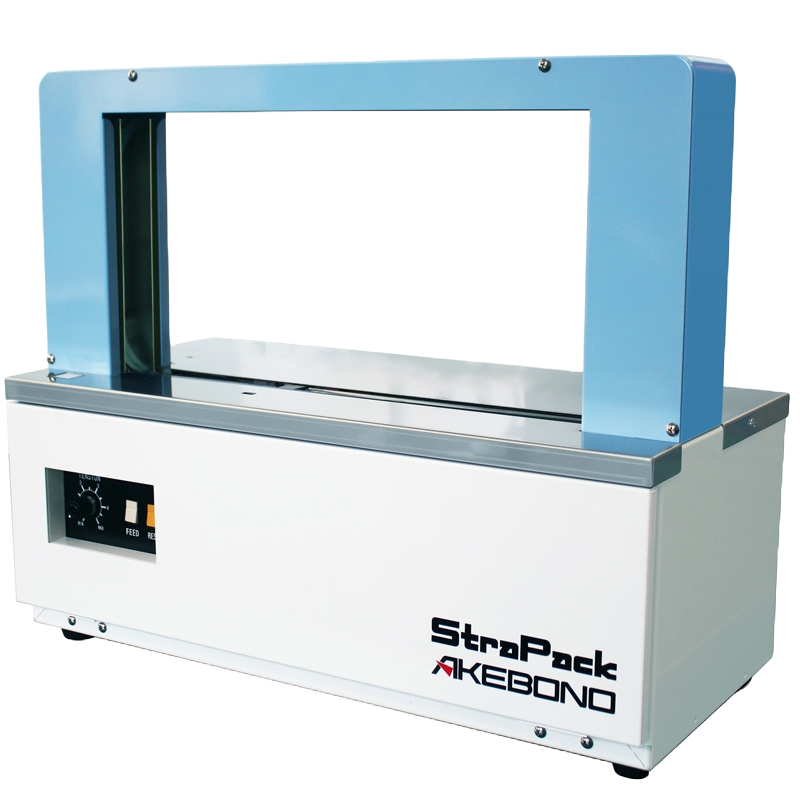

A durable strapping machine designed to withstand various packing environments; it is incredibly quiet to operate. This semi-auto strapping machine works with polypropylene strapping and will quickly tension, seal and cut strapping all in one go.

An efficient and high-speed automatic strapping machine, the SQ-800 offers up to 55 straps per minute. It has a wide range of tensioning modes for excellent flexibility and can be ready to operate in less than 25 seconds.

Ideal for high-demand environments, this automatic strapping machine has a built-in foot bar and adjustable height for operator comfort.

The StraPack OB-360B is a versatile auto strapping machine that provides high-speed branding, offering up to 30 cycles per minute. It can apply paper or film tape, giving the flexibility to use the type of banding that best suits your product.

Suitable for a wide range of packages, this automatic banding machine will band packages as small as 30mm wide x 10mm high, up to 420mm wide x 210mm high.

This affordable automatic strapping machine can produce up to 37 staps per minute, offering improved productivity.

It runs strapping from 9mm to 12 wide and provides easy changeovers and auto-re-feed features to reduce downtime.

If you’re looking for a strapping machine that’s perfect for securing pallets, the D-53PLT2 Semi-Automatic Pallet Strapping Machine is an excellent choice.

It can quickly strap pallets with polypropylene strapping in less than 2 seconds! This portable semi auto strapping machine can be easily moved around your warehouse and works with pallets as low as 350mm.

Strapping machines wrap bands (straps) of plastic or steel around a pallet of goods to ensure it is secure in transit. They ensure strapping is tight and properly secured. Tension can be adjusted, and straps are usually heat-sealed. It is seen as a vital piece of equipment by most logistics operations.

Semi-automatic strapping machines tighten a strap around a product that has been manually placed on the machine table. The operator has to wrap the strap around the placed product and then feed the end of the strap into a slot in the machine. This starts the process. When the strap has been tightened, the machine seals the end and cuts it off.

An automatic strapping machine has an arch over the table, via which the machine can automatically loop the strap around the product. Some are operated by a footswitch or by a push button, but fully automatic machines have conveyor belts and sensors to position a pack quickly and accurately before applying the strapping. Macfarlane Packaging offers machines that can secure a pallet in two seconds and others that apply up to 37 straps a minute.

Strapping machines are used to secure pallets and packs for shipping by applying tightened plastic or metal strapping. This strapping makes the load stable, ensuring easier handling while protecting the product being shipped.

It is a hand-held strapping tool with a friction weld function to seal a strap in place. It operates by generating friction between the ends of the strapping material, typically made of plastic or polyester, which creates enough heat to melt and fuse the ends together. This process forms a strong and secure seal, effectively holding the items being packaged in place. The friction welder is manually operated, allowing users to quickly and efficiently seal the strapping without the need for additional tools or equipment. It is a convenient and versatile solution for securing various types of packages and parcels during transit.

Hand-held strapping machines have a friction weld function that generates heat to weld a plastic strap in place, rather than having to tie it off or use an adhesive. Semi and automatic strapping machines also use friction welding to secure straps in place. The heat generated by this process causes the two ends of the plastic strap to fuse, creating a very strong bond.

The peak season for online shopping is fast approaching, and retailers are preparing to manage increased orders and demands.. If you are an internet r…

The last few years have proved to be challenging for UK business. 2024 has seen the continuation of a persistent labour and skills shortage in the log…

The speed of packing and shipping your goods is an important factor in meeting customer expectations for order fulfilment. Efficient packaging can be …

Aberdeen, Aylesbury, Banbury, Barnsley, Bath, Bedford, Bicester, Birmingham , Bolton, Bradford, Bridgewater, Bridport, Bristol, Burton-upon-Trent , Cambridge, Chelmsford , Cheltenham, Chester , Chichester, Colchester Cornwall, Coventry, Crewe, Derby, Devon, Dewsbury, Dudley, Dundee, Durham, Edinburgh, Essex, Exeter, Fareham, Gateshead, Glasgow Glossop Gloucester, Grantham, Harlow, Heathrow, Hemel Hempstead, Hereford, High Wycombe, Horsham, Hull, Inverness, Isle of Wight, Kent, Kidderminster, Lancaster Leamington Spa, Leeds, Lincoln, Liverpool , London , Luton , Manchester, Middlesborough, Milton Keynes, Newbury, Newcastle-under-Lyme, Newcastle-upon-Tyne, Norfolk, North Wales , Northampton, Nottingham , Oldham, Oxford , Plymouth, Reading, Salisbury, Sheffield, Shrewsbury, Shrewsbury, Slough, Somerset , Somerton, South Shields, South Wales, Stafford, Stockport , Stoke-on-Trent , Stratford-Upon-Avon, Sudbury, Sunderland, Surrey, Sussex , Teesside, Telford, Uxbridge, Wakefield, Walsall, Warrington, Warwick , Watford, Wigan, Windsor, Wolverhampton, Worcester, Wrexham, Yeovil, York.

You can also have automated strapping machines from Macfarlane Packaging delivered across Ireland and Continental Europe. Click to find your closest UK location or nearest Continental European site.