3 quick-install packaging automation systems for ecommerce

The peak season for online shopping is fast approaching, and retailers are preparing to manage increased orders and demands.. If you are an internet r…

Automated paper void fill and air pillow machines can dramatically reduce the time and hassle involved in packing your products securely, increasing throughput for effortless dispatch.

Protective automation systems dispense paper void fill and air pillows to ensure your product has all-round protection for safe transit. Most paper materials are recycled or recyclable and the inflatable plastic systems protect your products with air so pack weights are low.

Void fill and air pillow machines come in a range of brands, specs and sizes to suit all operations and environments. The speed and efficiency they offer can also help you reduce labour costs and reallocate resources.

The Buzz n’ Pack is a semi-automated packaging machine that firmly wraps products to a cardboard tray, creating a suspension pack that can be put into an outer cardboard box for shipping.

There are two models available – the Buzz n´ Pack 600er and Buzz n´ Pack 400er.

What are the benefits?

Our automation experts can seamlessly integrate protective automation machines into your packaging operation.

This is just a small range of the protective automation systems we can provide. If you can’t see what you’re looking for, contact us today to arrange an appointment with one of our automation experts. We can deliver tailor-made solutions for your operation.

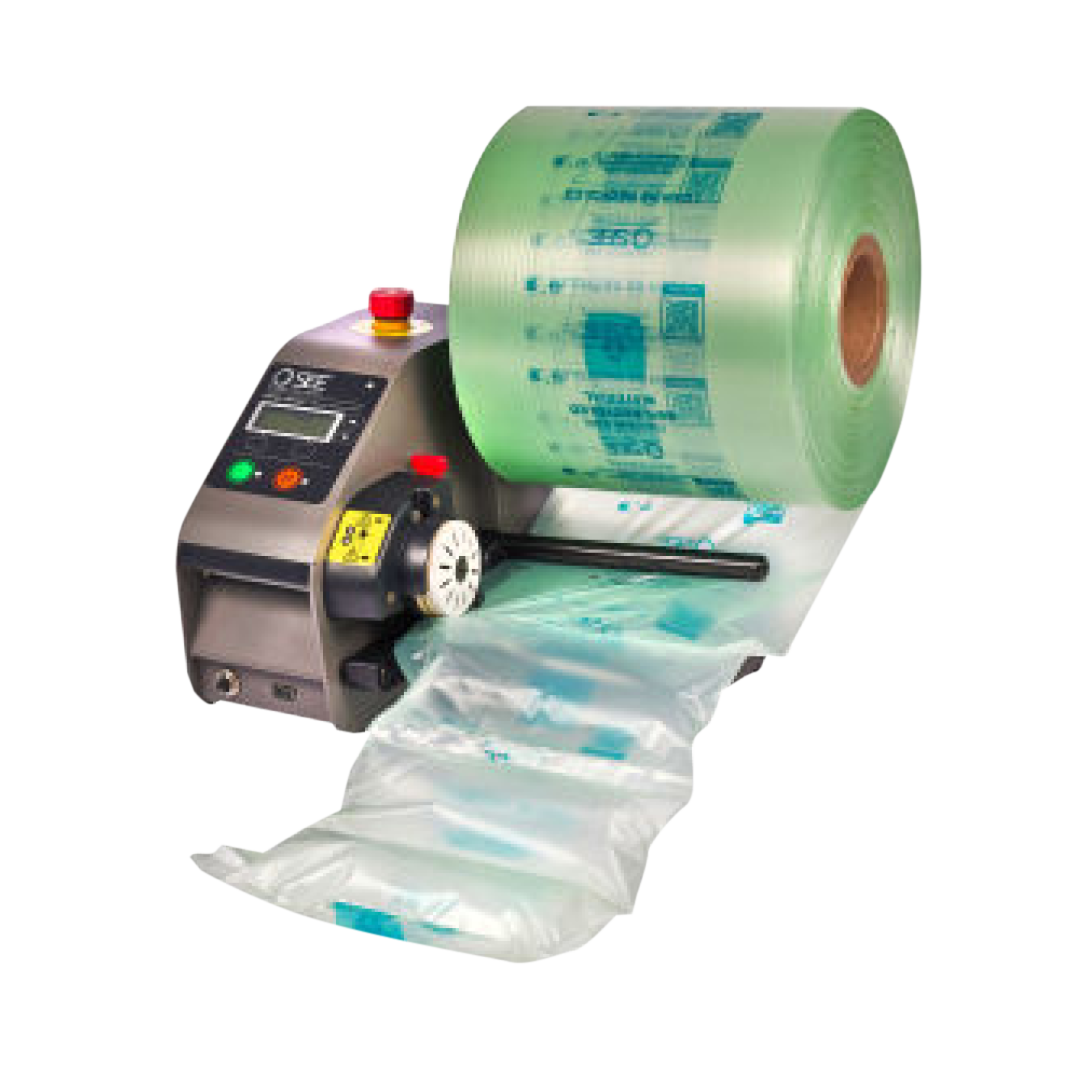

The Fill-Air Rocket® inflatable void fill system is an air pillow machine that’s ideal for producing on-demand protective material. Enjoy up to 100ft of void fill cushions per minute, ensuring you can keep up with demand in even the most high-paced packing environments.

Ideal for environments that need to combine superior product protection and speedy dispatch, Airsac® inflation machines work with our Airsac® inflatable packaging.

Macfarlane Packaging can supply a wide selection of Ranpak paper void fill and cushioning systems. Machines we can offer include:

An innovative bubble wrap on-demand system, the Sealed Air New Air I.B. Flex™ machine can produce up to 90 feet of inflatable packaging every minute. It works with a wide range of films, including recycled content options.

The MINI PAK’R® is a small, easy to use air pillow system that allows you to produce protective void fill on demand. Choose different types of air cushions to suit your protection requirements.

Air pillows offer several advantages for transit packaging. They are lightweight, reducing shipping costs by adding minimal weight while providing effective cushioning. The air-filled design absorbs shocks and impacts, safeguarding contents during transit. Air pillows also adapt to the shape of the items, filling void spaces efficiently and preventing movement within the box. They are quick to produce and easy to use, enhancing packing efficiency. Additionally, these pillows can be deflated, taking up less storage space before use. Many are made from recyclable materials, offering an environmentally friendly alternative to traditional packing materials like Styrofoam peanuts.

An air cushion machine is a device used to produce inflatable cushions and air pillows for protective packaging. These machines inflate various sizes of polyethylene or biodegradable film to create air-filled cushions, effectively securing and cushioning products during shipping and handling. They reduce packaging material waste and storage space compared to traditional packing materials like Styrofoam peanuts or paper.

Void fill refers to materials used to fill empty spaces in packaging to prevent items from shifting and getting damaged during transit. Common void fill materials include air pillows, foam peanuts, bubble wrap, and crumpled paper. These materials provide cushioning and stability, enhancing the safety of products during shipping and handling.

Void filling a box effectively is crucial to ensure the items inside are secure and protected during transit. Here’s a step-by-step guide on how to do it:

1. Select the Right Box: Choose a box that fits your items snugly, with just enough room for necessary padding. Excess space can lead to more movement and potential damage.

2. Wrap the Items: Individually wrap each item in protective material such as bubble wrap, foam sheets, or packing paper. This adds an initial layer of protection against shocks and scratches.

3. Place the Items in the Box: Arrange your wrapped items inside the box. Try to position heavier items at the bottom and lighter ones on top.

4. Add Void Fill Material: Use void fill materials like air pillows, foam peanuts, crumpled paper, or bubble wrap to fill empty spaces around and between the items. Ensure all sides, corners, and crevices are filled so the items cannot move inside the box. The goal is to immobilize the items, preventing them from shifting during handling and transport.

5. Test the Packing: Gently shake the box to see if there is movement. If you hear items moving, open the box and add more void fill until everything is snug.

6. Seal the Box: Once you are satisfied that the items are secure, close the box flaps and seal them with strong packing tape. Tape across the box seams and edges to reinforce them.

7. Label the Box: Mark the box as “Fragile” if it contains breakable items, and ensure that it is clear which side is up, if necessary.

Using the right amount and type of void fill material is key to protecting your goods in transit. Adjust the type and quantity based on the fragility and weight of the items you are shipping.

The peak season for online shopping is fast approaching, and retailers are preparing to manage increased orders and demands.. If you are an internet r…

The last few years have proved to be challenging for UK business. 2024 has seen the continuation of a persistent labour and skills shortage in the log…

The speed of packing and shipping your goods is an important factor in meeting customer expectations for order fulfilment. Efficient packaging can be …

Aberdeen, Aylesbury, Banbury, Barnsley, Bath, Bedford, Bicester, Birmingham , Bolton, Bradford, Bridgewater, Bridport, Bristol, Burton-upon-Trent , Cambridge, Chelmsford , Cheltenham, Chester , Chichester, Colchester Cornwall, Coventry, Crewe, Derby, Devon, Dewsbury, Dudley, Dundee, Durham, Edinburgh, Essex, Exeter, Fareham, Gateshead, Glasgow Glossop Gloucester, Grantham, Harlow, Heathrow, Hemel Hempstead, Hereford, High Wycombe, Horsham, Hull, Inverness, Isle of Wight, Kent, Kidderminster, Lancaster Leamington Spa, Leeds, Lincoln, Liverpool , London , Luton , Manchester, Middlesborough, Milton Keynes, Newbury, Newcastle-under-Lyme, Newcastle-upon-Tyne, Norfolk, North Wales , Northampton, Nottingham , Oldham, Oxford , Plymouth, Reading, Salisbury, Sheffield, Shrewsbury, Shrewsbury, Slough, Somerset , Somerton, South Shields, South Wales, Stafford, Stockport , Stoke-on-Trent , Stratford-Upon-Avon, Sudbury, Sunderland, Surrey, Sussex , Teesside, Telford, Uxbridge, Wakefield, Walsall, Warrington, Warwick , Watford, Wigan, Windsor, Wolverhampton, Worcester, Wrexham, Yeovil, York.

You can also have air pillow machines from Macfarlane Packaging delivered across Ireland and Continental Europe. Click to find your closest UK location or nearest Continental European site.