Using Automation to Speed Up Case Sealing

The speed of packing and shipping your goods is an important factor in meeting customer expectations for order fulfilment. Efficient packaging can be …

Automated packing systems are designed to optimise your packing process, so you can reduce costs associated with materials, productivity, transport and labour.

Packaging automation can drastically improve your pack line productivity and throughput. Dispatch more packs per hour to cope with demand, and reassign labour to key tasks.

Automating packing ensures the right size pack and right amount of material every time, eliminating waste. You can get more product delivered with fewer vehicles too – lowering your carbon emissions. Plus, packing consistently and to a high quality can help ensure you use the right amount of packaging every time. You’ll spend less on packaging supplies, create less waste and minimise your environmental impact.

Choosing to use packaging machinery can free up valuable space in your warehouse by eliminating the need to store excess packaging SKUs or bulky materials. Plus, as automated packing systems can help optmise the size of your parcels, you can get more product onto a pallet or delivery vehicle, controlling costs and fuel use.

How your team pack a product may differ from person to person. Packaging automation ensures quality control – minimizing damages and packaging material wastage.

Automation can seem like a big investment, but it can help you future proof for growth and seasonal demand by increasing your capacity significantly. Long-term this will help control costs as you grow.

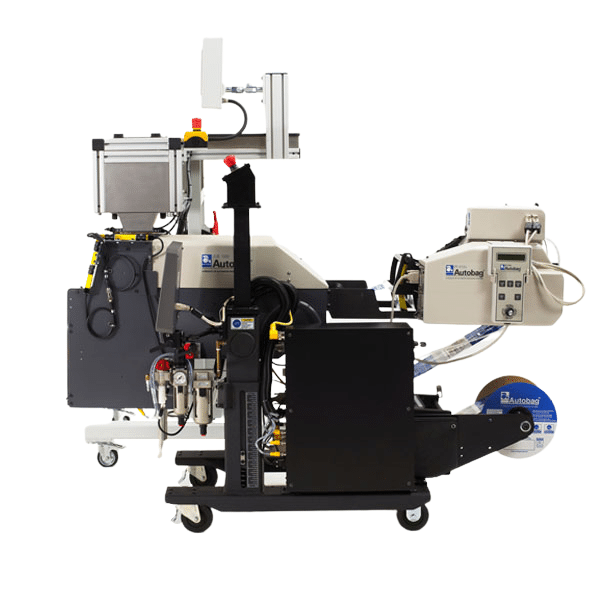

We can help with a wide range of packaging automation equipment from boxing machines and case erectors through to gummed paper tape dispensers and pallet wrappers – and everything in between.

We can help with a wide range of packaging automation equipment from boxing machines and case erectors through to gummed paper tape dispensers and pallet wrappers – and everything in between!

Are you wondering if now’s the time to introduce automated packing systems to your operation?

Watch this video for six signs that could indicate you’d benefit from packaging automation.

It details further signs that you could benefit from implementing automated packaging systems.

CLICK HERE TO GET YOUR CHECKLISTWant to see some of the packaging machinery and automation solutions we can provide or learn why upgrading to automation can benefit you? Watch a selection of our packaging automation videos today.

Got a question about packaging automation? Read our automation FAQs!

Packaging automation is the process of packaging products without the need for manual human intervention, using machinery to assemble or dispense packaging materials.

It can also involve the movement of product or parcels throughout a warehouse between picking, packing and dispatch sites.

There are lots of benefits of using automated packing systems. Some of the benefits include:

The difference between manual, semi-automated and fully automated packing processes is the level of human involvement in the packing process:

There are lots of ways to automate your packing processes. You can automate almost any part of packing procedures, but if you need pointers of where to start you will need to review your packing operation. This will help you identify any bottlenecks or processes that could be improved or automated.

Our packaging review can help you identify areas for improvement. You can also send us an automation enquiry and arrange an appointment with our experts, they can support you on your automation journey.

The type of packaging machinery you need will depend on the products you’re packing, your processes. your productivity goals and your warehouse space. You’d also need to factor in your budget.

There are lots of different types of packaging machinery available, from cardboard box and case erectors and auto-bagging machines through to pallet wrappers, heat shrink tunnels, in-line taping machines and much much more!

Why not get in touch to see how one of our packaging experts can help guide you?

How much packaging automation will cost your business will depend on the solution you choose.

Some small automated equipment, like water activated tape dispensers, can start from as little as £1,000. In contrast, custom solutions and high-volume equipment would be much more costly. However, it is important to remember that packaging automation often delivers a return on investment quickly – offering operational cost savings in other areas like labour, productivity, storage and transport.

If you’d like to cost packaging equipment or automation, contact us today.

The speed of packing and shipping your goods is an important factor in meeting customer expectations for order fulfilment. Efficient packaging can be …

Whether you’re a manufacturer, distributor or online retailer, time is money. That’s why looking for ways to optimise your production line and how…

Packaging automation can be a powerful tool for businesses that need to ship large quantities of products quickly. If you would like to increase produ…

We can help you with packaging automation throughout the UK. to you from one of our regional distribution centres. Our teams can provide packaging automation recommendations and services to and around the following locations:

Aberdeen, Aylesbury, Banbury, Barnsley, Bath, Bedford, Bicester, Birmingham , Bolton, Bradford, Bridgewater, Bridport, Bristol, Burton-upon-Trent , Cambridge, Chelmsford , Cheltenham, Chester , Chichester, Colchester Cornwall, Coventry, Crewe, Derby, Devon, Dewsbury, Dudley, Dundee, Durham, Edinburgh, Essex, Exeter, Fareham, Gateshead, Glasgow Glossop Gloucester, Grantham, Harlow, Heathrow, Hemel Hempstead, Hereford, High Wycombe, Horsham, Hull, Inverness, Isle of Wight, Kent, Kidderminster, Lancaster Leamington Spa, Leeds, Lincoln, Liverpool , London , Luton , Manchester, Middlesborough, Milton Keynes, Newbury, Newcastle-under-Lyme, Newcastle-upon-Tyne, Norfolk, North Wales , Northampton, Nottingham , Oldham, Oxford , Plymouth, Reading, Salisbury, Sheffield, Shrewsbury, Shrewsbury, Slough, Somerset , Somerton, South Shields, South Wales, Stafford, Stockport , Stoke-on-Trent , Stratford-Upon-Avon, Sudbury, Sunderland, Surrey, Sussex , Teesside, Telford, Uxbridge, Wakefield, Walsall, Warrington, Warwick , Watford, Wigan, Windsor, Wolverhampton, Worcester, Wrexham, Yeovil, York.

Macfarlane Packaging can also help with automated packing systems across Ireland and Continental Europe. Click to find your closest UK location or nearest Continental European site.

How can we help?