Understanding VCI Packaging: A Guide

Corrosion is the gradual deterioration of metals caused by the action of air, moisture or a chemical reaction (such as an acid) on their surface.

On face value, this is a naturally occurring reaction, but it’s a costly one. In the UK alone, a University of Edinburgh study estimated that corrosion costs the economy up to £80 billion per year. Globally, this figure is thought to be over $2.5 trillion.

Many industries can be impacted by corrosion, including construction, automotive, aerospace and marine sectors. If you’re producing, storing, handling or shipping metal-based products in these industries, you’ll want to ensure it’s protected.

So, what’s the solution? Enter VCI packaging. In this article, we’ll help you understand what VCI packaging is, the different types of VCI packaging available and the advantages it offers.

- 1.

- 2.

- 3.

- 4.

What is VCI packaging?

VCI stands for volatile corrosion inhibitor. VCIs are substances that slowly release an anti-corrosion compound into a sealed air space, protecting exposed metal surfaces.

VCI packaging, or anti-corrosion packaging, are packaging materials that can protect metal products during storage, handling and shipping and help prevent them from corroding.

Anti-corrosion packaging is made by applying a thin, invisible layer of a VCI compound to packaging materials. This layer stops water, oxygen and other contaminants from breaking down the metal products.

Types of VCI packaging

So, now you know what VCI packaging is, what types of VCI packaging are available? There are lots of options to choose from! Below, we’ve outlined the key types of anti-corrosion packaging available:

VCI Bags

Perhaps the most popular VCI packaging product, VCI bags are made from polythene coated in chemical compounds that prevent corrosion.

For smaller applications, like packing tools, screws or small machine parts, volatile corrosion inhibitor grip seal bags are a good choice. If you need a volatile corrosion inhibitor bag for larger applications, you can opt for large lining bags for boxes, crates and pallet boxes. Sometimes these are called Dolav liners or gusseted VCI bags. Just like the grip seal bags, they provide rust prevention.

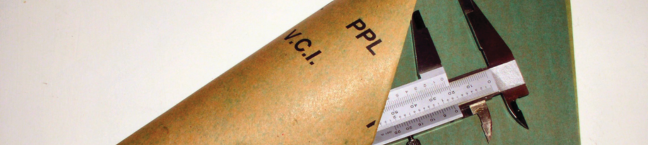

VCI Paper

Another popular anti-corrosive packaging product is VCI kraft paper. This rust inhibiting paper is supplied on a roll and one side of the paper is coated in VCI chemical. It’s suitable for protecting ferrous metal products during storage and shipping.

The other side of the paper can be coated in moisture barriers to further protect products.

VCI Cardboard

A cost-effective alternative to using a regular box with a VCI lining bag is VCI cardboard. It works in a similar way to anti-corrosion paper. The corrugated board is coated in a thin layer of VCI molecules, which are clear and invisible to the eye.

VCI Stretch Wrap

If you’re palletising goods that need rust prevention, you can make use of VCI stretch wrap. It’s ideal for palletising large metal goods, like engines or items that have odd profiles.

Like other anti-corrosion packaging, VCI stretch wrap is made using VCI molecules that are mixed into the polymer when the film is manufactured.

VCI Bubble Wrap

If you need your products to be protected from corrosion as well as knocks and shocks during shipping, VCI bubble wrap could be the answer.

Like VCI stretch wrap, rust-preventing bubble wrap has volatile corrosion inhibiting chemicals mixed into the material during manufacturing.

VCI Fabric

VCI fabric or metal wrap is made from woven high density polythene that is coated one side with corrosion inhibiting chemicals. It can be used with ferrous metals to prevent rust and non-ferrous metals to prevent tarnishing and oxidisation. It can also provide general surface protection.

The advantages of using VCI packaging

It might seem like a no brainer if you’re shipping metal products, but there are lots of advantages when using VCI packaging. This type of packaging can…

- Protect your products from corrosion and oxidisation, helping them stay in the best condition possible during shipping, handling and transit.

- Minimise product replacements, as it prevents harmful corrosion that could spoil your products.

- Reduce your costs, as they’re more effectively protected, you’re cutting the expense of replacements and reverse logistics.

- Give you flexibility and versatility, if you’re packing more than one metal product, many types of VCI packaging can allow you to project a range of different SKUs.

Protecting your products from corrosion

If you’d like support protecting your products from corrosion, rust and oxidisation, the Macfarlane Packaging team are here to help!

Our experts can design and recommend VCI packaging material that will protect your products and reduce your costs. Get in touch today.