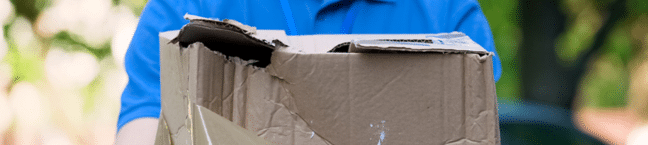

Shipping damages: common causes and how to prevent them

It’s estimated that over nine million UK shoppers have received a damaged parcel at some point. With billions of packages moving around the country, this should come as no surprise. But have you ever considered the impact of shipping damages?

Damages in transit can have an impact on both your reputation and your operating costs. It’s not a good look to have parcels (or any product) arrive damaged. The knock-on effects can include:

- Reverse logistics costs

- Product replacement costs

- Handling costs

- Reputation damage

- Loss of repeat sales

- Increased carbon emissions from logistics

If you’re experiencing damage in transit, this blog is for you. We’ll be taking a closer look at the common causes of shipping damage, the role of packaging in preventing damages, and some popular packaging materials that can protect your products.

-

1.

Common causes of shipping damages

- 1.1.

- 1.2.

- 1.3.

- 1.4.

- 1.5.

- 1.6.

- 1.7.

- 1.8.

- 2.

- 3.

- 4.

Common causes of shipping damages

So, what’s causing your parcels to be damaged? Here are 8 common issues that could be creating shipping damages:

1. Too much space in your pack

Are you using packaging materials that are too big for your product? This is an incredibly common cause of shipping damages as packaging that’s too big leads to product movement.

If your product can move easily during shipping, it is more likely to be damaged as it goes through the rigours of the supply chain. Movement can expose the most fragile parts of your product to the edges or corners of a pack, where crushing or knocks are likely to occur.

2. Outer packaging that isn’t fit for purpose

If you’re experiencing frequent damages, it’s worth considering the outer packaging you’re using.

For example, if you’re using a single wall cardboard box, you may need to trade up to a double wall or even triple wall box for extra protection. The specification for the outer packaging you need will depend on the size, weight, and fragility of your product as well as the shipping method and potentially any storage environment.

3. Not enough in-pack protection

If your outer packaging is working, but you don’t use the right in-pack protection, your products could be damaged during transit.

Just like a pack that is too big, if you don’t use the right quantity of packing material or it crushes easily under the weight of your product, damages could be on the horizon. Just like the outer packaging you choose, the packing material used inside also depends on product weight size and fragility, as well as the potential shipping journey it will take.

It is worth bearing in mind that the right in-pack protective packaging can often be a “Goldilocks moment” as you need to strike a balance between sufficient protection and not being wasteful.

4. Inconsistencies in your packing processes

You might be using the right packaging materials, but when your team pick, pack and dispatch your product, there could be inconsistencies.

In most packing operations, there will be significant human intervention and therefore human error. For example, one person may use too little void full material, or someone could choose the wrong size box. Packing guidelines or packaging automation can be great tools to combat this.

5. Incorrect or insufficient labelling

The right labelling can help to minimise damages. If your parcel doesn’t indicate there’s sensitive cargo inside, couriers or delivery handlers may not take as much care with it.

Some examples of labelling to prevent transport damage include: fragile markers on boxes, labels indicating any hazards (e.g. if it is chemicals) or even if a product is perishable (such as meal kits).

6. Poor handling during delivery

Chances are, lots of people will handle your product during the shipping and delivery processes. Even when your goods are properly labelled, they may be mishandled. Ensuring you have insurance or cover for improper handling can be useful in protecting your business against this.

7. Water or humidity damage

Inclement weather – particularly rain (we are in the UK!) can lead to packages getting damaged. If a parcel is left outside and it rains – the packaging can deteriorate and the goods inside end up spoiled or damaged. Not ideal.

In an industrial setting, humidity or condensation can lead to corrosion, warping or even mold, depending on the product. This is where climatic testing of your packaging can be a great option. Particularly if your goods may pass through different conditions.

8. Theft and tampering

Unfortunately, packages in transit are not immune to theft and tampering. In some instances, parcels may go missing entirely. In others, packages may arrive damaged.

For businesses shipping high end or high value products, security measures and tamper-evident packaging may be needed.

The role of packaging supplies in preventing shipping damages

The packaging supplies you use are critical when it comes to preventing shipping damage. In fact, protection is transit packaging’s primary function.

If you want to prevent damage ensuring you’re using optimised packaging, which is fit-for-purpose, is important too. As we alluded to earlier, packaging that’s the wrong size or specification can lead to damaged products.

Some tips to prevent shipping damages include:

- Choosing outer packaging (like a cardboard box) that’s big enough for your product and strong enough to hold its weight.

- Ensure empty space in your pack is filled with appropriate void fill material – this could be as simple as using bubble wrap or packing chips through to using air pillows, paper cushioning or foam. The right material will depend on the application. For example, do you need to block and brace or just fill the void?

- Put your packaging through supply chain simulations (like the testing facilities we have at our Innovation Labs) to see if you need to make any improvements.

- Have packing guidelines in place, so there is a standard for packing quality and consistency.

- Labels packs appropriately, to give handling guidance. You can also invest in impact or shock indicators, that can inform you if parcels are mishandled.

3 popular packaging materials to minimise shipping damage

So, what are common packaging materials that people use to protect their products? Here are three of the most popular protective packaging products we sell:

- Bubble wrap – a good all-rounder, bubble wrap has been a popular means of protecting products for years. The bubbles absorb shocks and knocks in transit, helping keep goods safe. It can take up a large amount of storage space though, so if this is a challenge for you – consider something more compact.

- Paper cushioning – compact paper blocks are a great space-saving option that can be used for cushioning as well as blocking and bracing. Paper cushioning is also recyclable and is available with high recycled content too – like Rankpak FillPak® Recycled Fanfold Paper.

- Airsac® – for electronics and bottles, Airsac® is a popular pre-formed protective packaging product that is available in a wide range of designs. It is made of recyclable film, that is only inflated upon use. So, it can be stored in a small space.

Support protecting your products

At Macfarlane Packaging, we have an extensive range of packaging materials and the expertise to help you prevent damage in transit and reduce your operating costs. Get in touch today.