How to use retention packaging to protect your products

Receiving a damaged product can be frustrating for customers and results in additional costs for businesses, as they need to process returns.

Using retention or suspension packaging can significantly improve the safety of your products during shipping, ensuring they reach customers in pristine condition. In this blog post, we will review the definition of retention packaging and its main benefits. We will also look at various applications and discuss whether this solution is right for your products.

- 1.

- 2.

- 3.

- 4.

What is retention packaging?

Retention packaging is a type of packaging where products are placed in a retention frame that uses film to secure them to a cardboard insert. This prevents the content from shifting during transit, protecting it from shocks and impacts.

This is slightly different from retention packaging, where the product is suspended within the outer packaging between two layers of highly resilient low-slip film, creating a cushion of air around the item. The innovative design helps absorb shock and impact throughout transportation, reducing the risk of damage to the product, even if the parcel is dropped several times.

The benefits of retention packaging

Suspension and retention packaging are both excellent block and brace solutions that offer a wide range of benefits, including:

- Shock absorption: Retention packaging secures the product inside the package, protecting it from shocks and impacts during transportation.

- Reduced damage: With retention packaging, the product is kept away from the outer walls of the package. This helps to reduce the chances of damage caused by vibration and rough handling.

- Versatility: Retention package can fit a wide range of product sizes and shapes, making it suitable for various industries, products, and packaging applications.

- Enhanced product presentation: Your products will look great inside the box, which helps enhance the unboxing experience.

- Cost reduction: This simple, cost-effective solution will help reduce your packing costs, from materials to processing returns.

- Minimised material waste: No additional void fill, such as foam or bubble wrap, is required. This helps avoid unnecessary waste and ensure you only use as much packaging material as needed to protect your products in transit.

- Space savings: The solution arrives flat-packed, taking up little space in your warehouse. It is also very easy and quick to assemble.

- Sustainability: The packaging is widely recyclable at kerbside, making it easy for customers to dispose of. It can also be made with recycled content and reused for return shipments.

- Customisation: Retention packs are available to buy off the shelf or can be made to your specific size and print requirements. A range of specialty features as well as non-standard options are also available to ensure the solution is right for your products. It can also be supplied with corrosion inhibitor and static barrier protection.

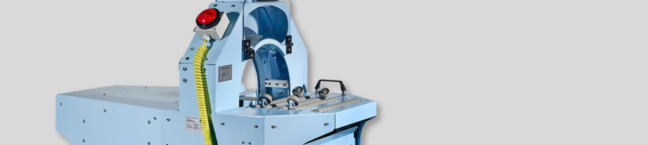

- Automation: If you’re looking to streamline your product wrapping process, automated solutions, such as the semi-automated Buzz n´ Pack® machines, are available for suspension packs.

These innovative, easy-to-use solutions provide you with top product protection while keeping your packing speeds high and your packing process consistent.

The machines use film to firmly wrap your products on a cardboard tray. With just one press of a button, you’ll have a retention pack ready to go into your outer cardboard box, ready for shipping. In this time, your packers can be preparing cardboard boxes and shipping information, which saves time and increases efficiency. There are two models available: Buzz n´Pack 400er, which accommodates S, M and L sized trays, as well as Buzz n´Pack 600er, suitable for S, M, L and XL tray sizes.

Is retention packaging right for my products?

Retention packaging is an excellent choice for a wide range of products and applications, such as electronics, glassware, spare parts, accessories, and consumer goods, as well as sensitive and fragile items needing that extra transit protection. This makes it a great option for many industries, including automotive, electronics, wine, health and beauty and pharmaceutical.

It can also be used to transport products of different sizes and irregular shapes, allowing you to reduce the number of packaging SKUs required and keeping your packaging inventory manageable. It is also a great tamper evident solution.

How Macfarlane Packaging can help

If you are not sure which packaging solution is right for your products, our team of packaging experts is here to help. We can guide you through the different options available and help you choose the most optimised packaging for your specific needs.

Contact us today to find out more about our suspension and retention packaging solutions and machines.