A comprehensive guide to anti-static packaging and conductive packaging

Are you shipping fragile and sensitive electronics? Then you may be looking for packaging to protect your products during handling and transit.

While electronics can benefit from the protective properties of standard packaging solutions, they may need specialist protection from electrostatic discharge or ESD.

ESD-safe packaging comes in many forms and is popularly known as anti-static packaging or ESD packaging.

In this article, we’ll provide a comprehensive guide to anti-static packaging, the science behind it and discuss the different types of ESD packaging available.

- 1.

- 2.

- 3.

- 4.

- 5.

Understanding anti-static packaging

So, what is anti-static packaging?

Anti-static packaging is packaging that can prevent electrostatic discharge (ESD) from damaging products.

It will sometimes be referred to as conductive packaging, static dissipative packaging, ESD packaging or shielding packaging too. These different types of anti-static packaging all perform similar functions, which we’ll explain later in this article.

Anti-static packaging is often made from materials like polythene or PET films that have additives that prevent static electricity. It can also be made from cardboard with specialist coatings, as well as foam.

The science behind anti-static packaging

Static electricity (or electrostatic discharge) might not seem like a big deal in everyday life. You’ll get a small shock from touching another person or object and think nothing of it.

These shocks are created by electrostatic discharge moving between two objects (or people!). However, this static electricity can create a large amount of heat. This in turn can cause electronic devices to break or become faulty.

Due to this, electrostatic discharge is an extra risk during storage, shipping and transit. Which is where anti-static packaging comes in. It provides protection from the usual rigours of shipping AND can prevent the build-up of static charges, as well as dissipate them.

Why anti-static packaging is important

Electrostatic discharge damage can be costly. It’s estimated by the ESD Association that damages caused by static in the electronics industry can run up to $5 billion. Some major companies suggest that ESD is responsible for 25% electronics part failures too.

In essence, anti-static and ESD-safe packaging help prevent the costly risk that static-sensitive microchips, motherboard and other electronics components might encounter.

So, what types of anti-static packaging are there?

Types of anti-static packaging

Anti-static packaging is often used as a catch all term of packaging that prevents and resits electrostatic discharge. As mentioned earlier in this article, it also known as conductive packaging, shielding packaging and dissipative packaging.

While these terms are sometimes used interchangeably, there are some technical differences:

- Anti-static packaging – this prevents electrostatic charges being created when products may rub against other objects or surfaces.

- Conductive packaging – this type of packaging conducts any potential static charges away from sensitive parts, keeping any flow of electricity under control. It does not accumulate static charges.

- Shielding packaging – this type of ESD-safe packaging provides a barrier that reduces electrostatic discharge.

- Dissipative packaging – this type of packaging slows down the flow of any static charges, rather than directing it like conductive packaging.

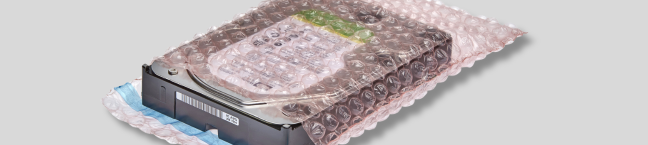

Across these types of anti-static packaging, the actual packing material can take many forms. Popular products include anti-static bags, anti-static bubble wrap, anti-static bubble bags and anti-static foam. Usually, these types of ESD packaging are coloured pink, so their distinguishable from their counterparts that aren’t ESD-safe.

Other anti-static shielding bags are metallised to provide protection as well.

In addition to these popular packaging products, you can also get anti-static packaging made from cardboard and corrugated plastic. Examples of these products include:

- Corstat® cardboard – this cardboard creates a Faraday Cage effect, protecting products inside it. It can be used to make anti-static boxes, layer pads, totes and dividers. It can also be used alongside anti-static foam fittings, to provide an all-round ESD-safe packaging solution.

- Corriplast® corrugated plastic – this corrugated plastic is Carbon loaded and provides protection from static charges. It’s very strong and durable, and is resistant to water, grease and other liquids. It’s also suitable for clean room environments. It can be made into boxes, collapsible totes dividers and layer pads, or custom designs.

The benefits of using anti-static, conductive and ESD packaging

Anti-static packaging can provide many benefits. Particularly if you’re an electronics manufacturer or are moving electronic components in industries like automotive, airspace and medical.

Using ESD-safe packaging can deliver the following benefits:

- Reduced damages – anti-static packaging will ensure your products are protected from static damage, as well as the usual knocks, shocks and drops that could be experienced during handling and shipping.

- Reduced returns & reverse logistics – it can help reduce costly returns, reverse logistics and expensive product replacements by minimising the risk of damages.

- Improved productivity – the benefits provided by anti-static packaging will remove hassle from your packing operation by reducing the handling of returned goods. This will allow you to focus your resources elsewhere.

- Lower packaging costs – efficient, right-size anti-static packaging can help you lower your packing costs. Reducing damage will minimise replacement and reverse logistic costs in your operation too.

Specialist support developing anti-static packaging solutions

Are you looking for ESD-safe packaging?

At Macfarlane Packaging, we have extensive expertise in creating all sorts of packaging solutions. We have anti-static bubble bags, anti-static bubble wrap and anti-static foam rolls available from stock.

Plus, our specialist manufacturing brand can support you with custom packaging designs, including conductive packaging like Corriplast® corrugated plastic, anti-static inserts and conductive Corstat® cardboard packaging.

Get in touch today for more information.