Correx® packaging applications and advantages

Most people know what cardboard, stretch wrap, polybags and other common forms of packaging look and feel like (and what they are typically used for).

However, although many will likely have seen it used for estate agent signs, you may not have considered how you can use Correx® for packaging.

This article provides an explanation of what Correx® packaging is, its typical applications, and the range of benefits it can provide for your business.

- 1.

- 2.

- 3.

- 4.

Correx® packaging

So, what is Correx® packaging?

Correx® is a corrugated plastic (polypropylene) material. Manufactured by Corplex, it is available in various thicknesses and strengths, plus a wide range of different colours.

Specialist packaging companies can convert the material similarly to corrugated cardboard, including die-cutting. In fact, it is sometimes referred to as plastic cardboard. As a result, many of the packaging products produced using cardboard can be manufactured using Correx® instead.

However, its properties mean that Correx® packaging can also be used in various industries and applications where cardboard is unsuitable.

Advantages of Correx® packaging

So, what are the advantages of using Correx® packaging? Well, there are many unique benefits that the material and packaging produced using it possess.

Durability and strength

Firstly, Correx® packaging provides a considerably higher degree of strength and durability than cardboard.

This means that Correx® boxes and other products have a longer lifespan than cardboard equivalents, which are typically only used for single-trip applications. Therefore, Correx® packing is suitable for returnable packaging applications in industrial supply chains, where tote boxes and containers are used across 100s of trips.

This reusability also means that Correx® packaging typically has a lower lifetime cost per trip than cardboard.

The other significant benefit of the material is that it is stronger, can carry greater weight, and provides improved protection for contents.

Water-resistant

Besides increased protection from mishandling and impact, Correx® packaging is also water resistant.

Besides helping to protect contents by keeping them dry, it also means that Correx® is suited to conditions that may be damp or be exposed to inclement weather.

Similarly, Correx® is also resistant to most chemicals, which are generally inert and unreactive.

Easy to clean

Being resistant to both water and chemicals, and coupled with the smooth surfaces, means that Correx® packaging is easy to clean. This benefit can help extend the life of any returnable packaging you use.

This also means that Correx® packaging can be suitable for clean room use. In fact, several additional benefits lend the material to this type of application. Correx® is suitable for sterilisation (including EtO, gamma, and autoclave methods) and does not shed fibres that could potentially contaminate samples.

Size flexibility

Whilst Correx® boxes can offer excellent strength and performance, moulded plastic options such as euro containers are typically more robust and competitively priced.

However, Correx® packaging has one key advantage over moulded plastic options: the size flexibility it offers.

As with corrugated cardboard boxes, Correx® packs can be designed and manufactured in almost any size and shape. This has numerous benefits.

Firstly, tailoring the size to your specific products can help increase protection. Secondly, it ensures your handling containers are more space efficient – you are not paying to store, ship or handle empty space within the box. Thirdly, this space efficiency can significantly reduce your transportation costs. And finally, it can help reduce your carbon emissions (due to shipping more products per load).

Bright colours and print

Correx® is available in a range of bold colours, including blue, red, green, yellow, white, silver and black. You can also specify bespoke hues, subject to minimum order quantities.

However, even if you are using a standard colour, Correx® packaging provides a bold, vibrant appearance that can attract attention from potential customers.

Correx® can also be easily printed using screen or digital print methods. This allows you to add your company branding, handling instructions, safety symbols, and other important or useful information.

What applications are there for Correx®?

So, considering these benefits, what applications is Correx® packaging suited to?

Returnable packaging

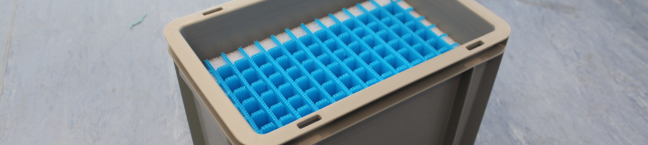

Perhaps the most obvious and common application for Correx® packaging is in returnable supply chains. Particularly popular in automotive and aerospace, Correx® tote boxes, containers, and dividers are widely used to transport parts, assemblies, components and finished products between manufacturing sites.

The size flexibility, ease of handling and longevity make them perfect for this application.

Handling

Similarly to supply chain packaging, Correx® is an excellent choice for in plant handling and lineside storage of parts and components.

Parts can be easily brought to staff working on production lines, with dividers allowing for easy unpacking and quick visual stock checks.

Picking bins

A different yet equally popular application for Correx® is for manufacturing picking bins.

Picking bins are effectively open-front boxes, often stackable, that are placed into warehouse racking to organise product inventory. They allow order pickers and fulfilment teams to quickly locate and “pick” items to fulfil orders. As such, their popularity amongst eCommerce businesses and third-party logistic companies has grown rapidly over the past ten years.

Medical and pharmaceutical

As mentioned previously, Correx® is a strong option for medical, clean room and pharmaceutical applications.

Benefits include no shedding of fibres, ease of sterilisation, ability to be cleaned and reused, plus the broad range of designs and custom sizes.

Consumer packaging

Finally, due to its bold colours and suitable printing surfaces, Correx® can be used for retail and consumer applications.

However, due to the additional cost compared with corrugated and the increased difficulty for end users to recycle, it is best suited to added-value packaging applications (i.e., where the consumer retains the pack for ongoing storage and organisation of the purchased products).

Correx® has even been successfully used for long-term in-store FSDUs (free-standing display units) and point of sale.

Summary

Correx® packaging can be a great option for many businesses and applications, potentially reducing long-term costs, lessening environmental impact, and providing improved usability and presentation.

GWP Correx®, part of Macfarlane Packaging since 2021, are one of the UK’s largest converters of Correx® material. With experienced designers, extensive customer support and a team of material and product experts, you can not only source the widest range of Correx® packaging but also request advice on the optimum solution for your specific application.