A guide to protective cases and their uses

If you need to store, transport or organise any tools or equipment, then this protective case guide can help you select the best option for your application.

Protective cases come in many forms. This includes well-known waterproof options, such as Peli cases, through to widely used custom flight cases. Everyone from engineers, service technicians, medical professionals, and even sales teams presenting samples can all benefit from protecting essential items with a suitable case.

The benefits of selecting the right case can be significant. For example, an engineer on-site may be unable to carry out their tasks if damage occurs to their equipment in transit. Similarly, a suitable sample case can be the difference between securing a large order in a sales pitch or walking away without a deal.

But what protective case options are available to your business?

- 1.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

Waterproof cases

Waterproof cases are one of the most widely used types of protective cases.

They provide a completely water-tight seal, protecting their contents from moisture and dust entering the case. Most waterproof cases have an IP (ingress protection) rating, which indicates the degree of protection they offer. This performance makes them ideal for protecting any tools or equipment that could become damaged if they get wet.

Besides protection from water and dust, waterproof cases also tend to be amongst the toughest and most durable cases available. They protect from knocks, impact, mishandling, and even being crushed. Besides this, nearly all waterproof cases feature a manufacturer’s lifetime guarantee.

Larger waterproof cases usually have wheels and telescopic handles, whilst all cases feature secure latches and ways to padlock the case (securing the contents).

Popular brands of this type of case include Peli, Storm, Explorer, SKB, Nanuk and B&W.

Their high performance means they are widely used in the defence sector to protect “mission-critical” equipment. They are, however, widely used by service technicians, engineers, film and broadcasting professionals, or anyone that needs to protect fragile, sensitive or expensive equipment.

Roto-moulded cases

Roto mould cases are similar to waterproof cases in that they are entirely water and dust tight. However, they are arguably the most heavy-duty protective case option available.

Manufactured using rotational moulding, the cases are incredibly tough and durable. This strength is enhanced by their ribbed design and increased material thickness in the corners (due to the moulding process).

Features of roto mould cases include being stackable (many having a locating pattern), pressure relief valves, various lid options and a wide range of colours. Specialist “rack mount” cases are also available to protect electronic equipment.

Roto mould cases are used extensively by military forces around the world. However, they are also popular for transporting large and heavy parts and components, for example, within the aerospace industry.

Popular options include those offered by Peli Hardigg (ISP2 and single-lid ranges) and SKB.

Aluminium cases

Aluminium cases are another option commonly used by aerospace and other technical industries and manufacturing businesses. However, their main benefit is their light weight – making them ideal for safely shipping parts and equipment internationally.

Aluminium protective cases provide several other benefits too. They maintain performance at high and low temperatures, unlike plastic cases that can soften or become brittle. They also do not rust, absorb impact, and are easy to clean.

This final point also means that professional sports teams commonly use aluminium cases as “kit skips”. They transport sports kit and equipment to training sessions and matches, with their easy clean surfaces making them ideal for transporting dirty kit too. All Premier League football teams use this type of case.

Zarges are the market leader in manufacturing aluminium cases, although Bott is also a popular option.

Plastic carry cases

It is not uncommon to have some equipment that doesn’t need a high level of protection. Or that will never be exposed to adverse conditions or mishandling. Lightweight plastic cases can be an excellent choice for applications such as this.

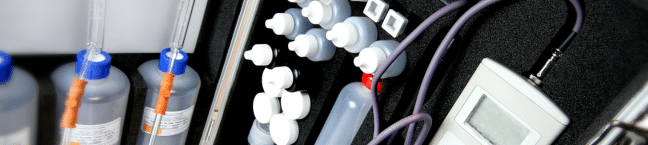

Similar to waterproof cases in appearance, plastic carry cases are a cost-effective option where the performance of a waterproof case is not required. As such, service engineers, field technicians and similar professionals may use this type of case for storing and organising tools and equipment.

This type of case is also widely used by salespeople to present samples in sales pitches and presentations. Some businesses even use them to add value to their products (e.g. a set of items are supplied in a case that the customer retains).

Hofbauer. Maxado, Rose Plastic and W.Ag make a range of plastic case options, meaning there will likely be a suitable size and style for your specific requirements.

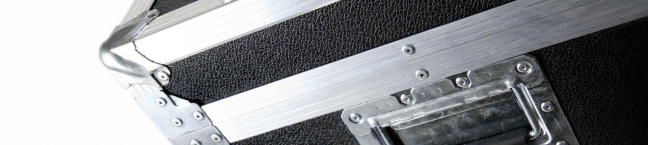

Flight cases

If an off-the-shelf case isn’t exactly right for your business, you can specify a custom-made flight case instead.

Made using plywood or composite panels with metal edging and corners, the significant benefit of flight cases is the ability to manufacture them to almost any size. This size flexibility can significantly improve the efficiency of your transport and reduce emissions (as you are not paying to ship fresh air in a standard-sized case that is slightly too big).

Whilst they are not as durable as roto-moulded or waterproof options, they still provide good protection, along with options such as castors, wheels, handles, and different lid designs/heights.

Flight cases have long been associated with media, broadcasting and touring musicians (often referred to as road cases) but are also suitable for safely transporting almost any parts or equipment.

Foam inserts for cases

It is important to note that you can enhance all of the protective cases detailed here by adding foam inserts.

You can choose to source many of the waterproof cases with what is known as cubed or “pick and pluck” foam, where the case user can create their own semi-custom insert by removing 1cm cubes of foam to create pockets for their equipment.

However, custom foam inserts manufactured using plastazote foam provide many additional benefits.

Firstly, custom foam inserts allow for recesses that are exactly the shape and size of your equipment. Secondly, it is possible to use software that can calculate the exact thickness of foam required to provide the optimum level of cushioning protection. Many foam converters will mistakenly add too much foam to be sure items are protected, but as well as costing more, this can often make the foam less effective.

Another advantage of custom foam inserts for protective cases is that you can use different colours for the insides of any pockets. This effect, known as tool control or shadow boards, enables the case user to quickly identify if any parts or tools are missing from the case.

And finally, it is even possible to laser etch your company logo, part numbers or other information directly onto your protective cases’ foam inserts.

Other customisation options

Besides foam inserts, there are several other customisation options you can consider.

For example, it is possible to add printed branding and handling instructions to the exterior surfaces of most protective cases.

Besides this, many cases allow for a “bezel kit”. These will enable you to mount electronic equipment directly into the body of the case.

Many of the standard cases offer padded inserts and dividers, additional carry straps, and some even allow you to swap the standard lid with a transparent version (displaying the contents at all times).

What protective case is best for your business?

Deciding which case is the best option for your business or application can be challenging. So, if you would like guidance on selecting the most appropriate case, or any other types of protective packaging solution, please do not hesitate to get in touch. Our expert team can help your choices regarding customisation, or other advice on avoiding damaging your tools or equipment.