Chilled packaging: a quick guide

The meal kit market is booming in the UK. By 2025, it’s estimated that it will be worth £1.5billion. During Covid-19, many restaurants and food businesses diversified to include home delivery and this growing market doesn’t show signs of slowing down.

If you’re a food delivery business or are thinking about starting one up, you probably need to think about the packaging you’re using (or will be). So, have you ever heard of chilled packaging? Read our guide to learn more…

What is chilled packaging?

Chilled packaging, sometimes referred to as temperature-controlled packaging or thermal packaging, is packaging that is designed to preserve the temperature of products during shipping. It protect goods such as food (including meat, fish, dairy, and prepared food), drinks, medicines, and other temperature-sensitive products.

In practice, temperature-controlled packaging maintains ambient, chilled, or frozen temperatures. It is widely used in cold chain logistics (where goods throughout the supply chain require low temperatures). This often involves a series of refrigerated production, storage, and transport hubs. Chilled packaging is a critical part of cold chain logistics.

What types of chilled packaging are there?

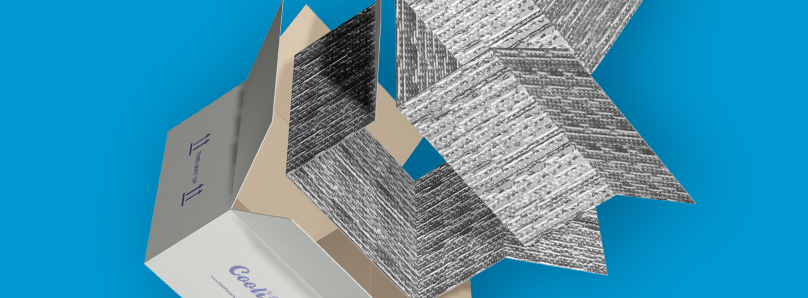

There are lots of different types of thermal packaging options to choose from. Most include:

- an outer cardboard box

- an insulating material

- a coolant (e.g. ice packs)

The most common insulating materials are paper padding, corrugated paper, or foil lined bubble sheets. These all help maintain the temperature within your pack. Other chilled packaging insulating materials include polystyrene, sheep’s wool, and even recycled fibre materials.

Coolants are usually products like ice sheets and gel packs or dried ice for frozen shipments. They lower the temperature in the pack, working in combination with the insulating material to keep the temperature within a consistent range. The type of coolant you need will depend on the temperature you need to keep your products at.

Temperature controlled envelopes for smaller products are available for small products. Temperature-controlled pallet covers and bulk chilled packaging options deal with high volumes or large items.

Can chilled packaging be reused or recycled?

Some materials used in chilled packaging are easy to recycle, others less so.

If you’re using a cardboard box lined with paper padding, like our RecycoolMe shipper, you will be able to recycle the majority of the temperature controlled packaging you’re using. Some materials cannot be recycled at kerbside, however. These include insulating materials with a metal lining, and coolants. The consumer must recycle these through regular waste streams.

Is there a right way to use chilled packaging?

Yes, there is an optimum way to use chilled packaging! Our specialist temperature-controlled packaging team recommend that you:

1 – Assemble your outer packaging and line it with your insulating material

2 – Insert your temperature sensitive products

3 – Insert your frozen coolants into the pack. Because cold air is dense it moves downwards, so we recommend putting coolants on the top of product, not underneath it. If you’re packing multiple layers of chilled product, you can interleaf layers of goods and coolant. Additionally, you can pack coolant down the side of product, if you have room to do so

4 – Insulating material should then be placed on top of your goods and coolant. This important step helps maintain a constant temperature in your thermal packaging

5 – If you need additional protection in the pack, like void fill, this should be above / outside the insulating material to maintain the temperature-controlled environment. After this, your chilled pack is ready to seal and send.

For more information about chilled packaging and how we can support you, get in touch with the Macfarlane Packaging team today.