Macfarlane Packaging launches new rapid box assembly system

Macfarlane Packaging today announces the launch of an innovative new rapid box assembly system that helps packers build cardboard boxes in seconds and increase packing efficiency by up to 70%.

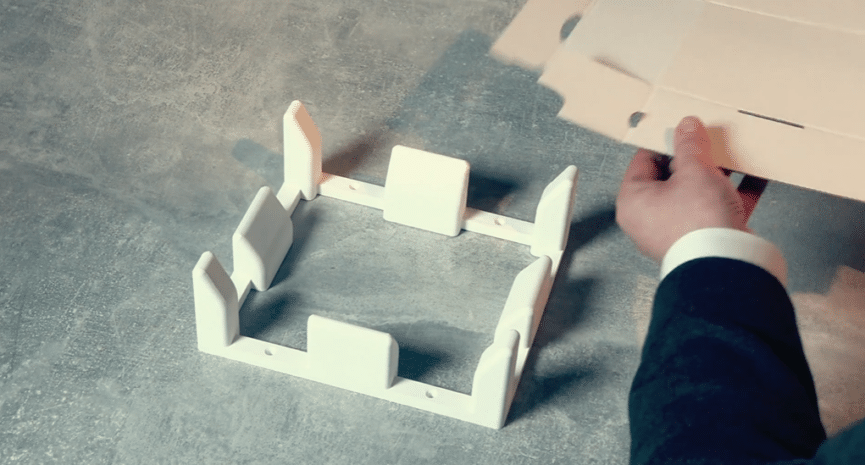

Created by Macfarlane’s Innovation Lab team, the new patent-pending solution has been designed to increase operational productivity by reducing manual box assembly times from 10 seconds to less than three seconds.

The unique piece of packaging equipment will be made-to-order for Macfarlane customers and works with Macfarlane-exclusive box designs that have been optimised to provide more performance strength while using less material – increasing pallet fill and reducing transportation costs /CO2e.

The 3D printed units can quickly assemble boxes up to 400mm x 300mm, with variable options on depth. This makes the solution ideal for online and multi-channel retailers packing a high volume of small parcel size packages. Combined with Macfarlane’s optimised box design, the solution provides an affordable alternative to using more costly crash-lock boxes.

Richard Garratt, Head of Design at Macfarlane Packaging commented: “With an increasing number of businesses trying to balance the complexities of supply chain efficiency and operational cost reduction alongside sustainability this is a potential gamechanger for some Macfarlane customers.

“The rapid box assembly and exclusive box designs were developed at our Innovation Labs and represent an opportunity for customers to reduce pack times, lower costs, cut material use and lower overall CO2e associated with their packaging.”

See the Macfarlane’s rapid box assembly frame in action…