Cardboard boxes: an essential guide

Understanding the language of cardboard boxes can be tough for small businesses and large businesses alike. What’s the difference between single and double wall boxes? What is fluting? Who is FEFCO?

If you buy cardboard boxes or want to use them for your small business packaging, it can be useful to understand the basics. Knowing how to measure a box, what board grades are and what the most popular styles of cardboard boxes are can help you save time and money when it comes to packaging.

Our essential guide will cover all the basics you need to know, so you can get started with cardboard boxes…

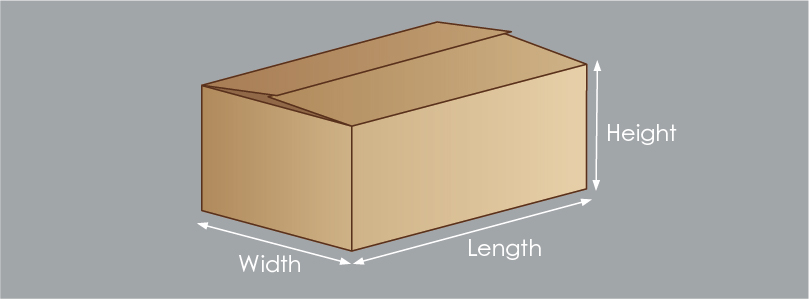

How to measure a cardboard box

The first thing you’ll probably need to know is how big you need your cardboard boxes to be. When measuring the size of cardboard boxes, you always need to know what the internal dimensions of the boxes will be. This is the usable space that your products will go in.

Cardboard box dimensions are usually expressed as: Length (L) x Width (W) x Height (H).

- Length = the longest opening dimension

- Width = the shorted opening dimension

- Height = the dimension from the top of the opening to the base of the box (sometimes referred to as depth).

We always recommend measuring cardboard boxes in millimeters. For example: 600mm x 300mm x 250mm.

The cardboard boxes you choose should accommodate the range of product you stock – from the smallest item to the largest – as well as any protective packaging (e.g. bubble wrap or paper cushioning) you’ll need for shipping.

Getting the size of your cardboard boxes right is important as it can have a knock-on effect across your supply chain from minimum order quantities, through to storage and customer experience. For example, if your cardboard box is too big, it can lead to product damage through in-pack movement and excess packaging waste. Plus, if your boxes are overly big, you’ll be using up extra storage space, adding to your costs.

What are cardboard boxes made from?

Next, you’ll need to understand what your cardboard box is made from. The different types of cardboard and box styles all influence the strength and performance of your packaging, as well as the cost.

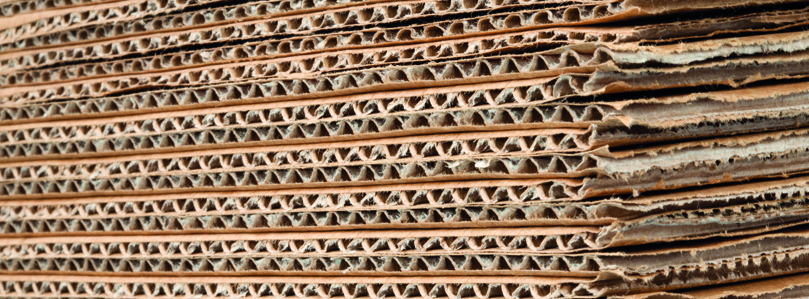

Most cardboard boxes used for shipping products are made from corrugated cardboard. This type of cardboard is made from a fluted or waved piece of paper sandwiched between two flat pieces of paper.

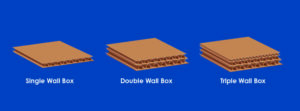

There are three main types of corrugated cardboard you’ll come across when it comes to boxes:

- Single wall – one layer of fluted board is sandwiched between two sheets of liner board. This would make a single wall cardboard box.

- Double wall – two layers of fluting that are glued to three layers of liner board. This would make a double wall cardboard box, which is stronger than using single wall alone.

- Triple wall – three layers of fluting are laminated with four liner boards. This would make a triple or tri-wall box – the most heavy-weight and durable of all boxes.

These different types of corrugated cardboard influence the strength of your cardboard boxes. So do the grades of paper and type of fluting used.

Board Grades

The board grade refers to the weight, quality and type of material used to make the cardboard. Depending on the intended use of a box, the board weight will range from 125gsm to 300gsm. The heavier the weight of the paper the stronger the box will be. It’s worth noting that the GSM description of the board may relate to the performance of the board, and not the actual weight. In other words, it has the properties of a heavier material.

As well as the weight of the paper, you may hear people say cardboard is “kraft” or “test”. These terms relate to if the paper used in manufacturing is virgin material (kraft) or recycled material (test). Some boxes may combine both kraft and test cardboard.

Fluting Profiles

Fluting is the wavy or fluted piece of paper inside corrugated cardboard that helps to strengthen the boxes. It’s what creates the stripey grain like texture you would see when looking at a piece of cardboard.

It can vary in width and size and is often referred to by letter e.g., “B flute”. Single wall boxes will only have one type of fluting, but double and triple wall boxes may use multiple fluting profiles.

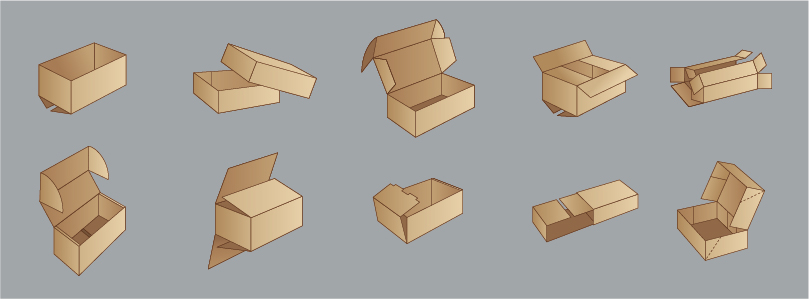

What styles do cardboard boxes come in?

After establishing the size and board type of your cardboard boxes, you’ll need to think about their style or design.

You can choose from a range of internationally standardised boxes. All of these are dictated by FEFCO – the European Federation of Corrugated Board Manufacturers.

There are nine different categories of cardboard boxes, which are then broken down into different styles. The most common box style is 0201, which is a slotted type of box. Another common box style is 0427, which is a folder style box, sometimes called a pizza style box.

What else do you need to know?

Once you’ve identified the size of box you need, as well as the board grade and style, you’ll be ready to get a price for cardboard boxes you want to order. You could choose from stock boxes or opt for custom packaging. Remember, if you go the custom route, your order will be subject to minimum order quantities (MOQ). This often depends on the size of the box – the smaller it is, the higher the MOQ.

Plus, when you order cardboard boxes, they will be delivered flat packed for easy storage! Most boxes require sealing with packing tape prior to dispatch, so you’ll need to order this as well. Watch out for future Packaging 101 guides, where we’ll explain tape in more detail too!

If you need help with your packaging or choosing the right cardboard boxes for your business, we’re here to help. Macfarlane Packaging can provide protective packaging solutions for businesses of any size from small businesses through to national and multi-sited operations. Get in touch today…