3 steps to bEPRprepared

THINK SMARTER & LIGHTER

EPR fees are calculated using the weight of the packaging you put onto the UK market.

So, making your packaging lighter is key. Re-evaluating your packaging designs can lead to using less material, lowering total weight and consequently EPR fees.

THINK SMALLER & LESS

Reviewing your packaging and eliminating excess material can cut unnecessary waste and reduce your EPR liability. Balancing protection vs. waste is essential to avoid damage and costly returns.

THINK RECYCLING

EPR fees will be modulated – based on material type and eventually, how easy they are to recycle. Easier to recycle packaging will attract lower fees.

Making prudent switches to easier to recycle packaging can help you prepare now and offset future fees. This should always be done with your supply chain and packaging needs in mind!

bEPRprepared with Macfarlane Packaging’s EPR Services

At Macfarlane Packaging, our experts are here to help you prepare your packaging materials and processes to mitigate the impact of Extended Producer Responsibility.

From informative guides, assessing your EPR costs and helping you redesign your packaging material through to support collecting your essential packaging data, we’ve got a solution for you.

EPR Information & Guides

See more in-depth information about the incoming Extended Producer Responsibility scheme with Macfarlane Packaging's range of handy guides!

EPR Cost Assessments & Packaging Reviews

Using less packaging will reduce the tonnage you're putting on to the UK market. Making use of intelligent, optimised packaging design can help you achieve this while protecting your products.

Packaging Evaluation & Review Service

90% of your packaging costs can be hiding behind the unit price you pay. And with EPR fees incoming, the packaging you use and how you use it will be more critical than ever.

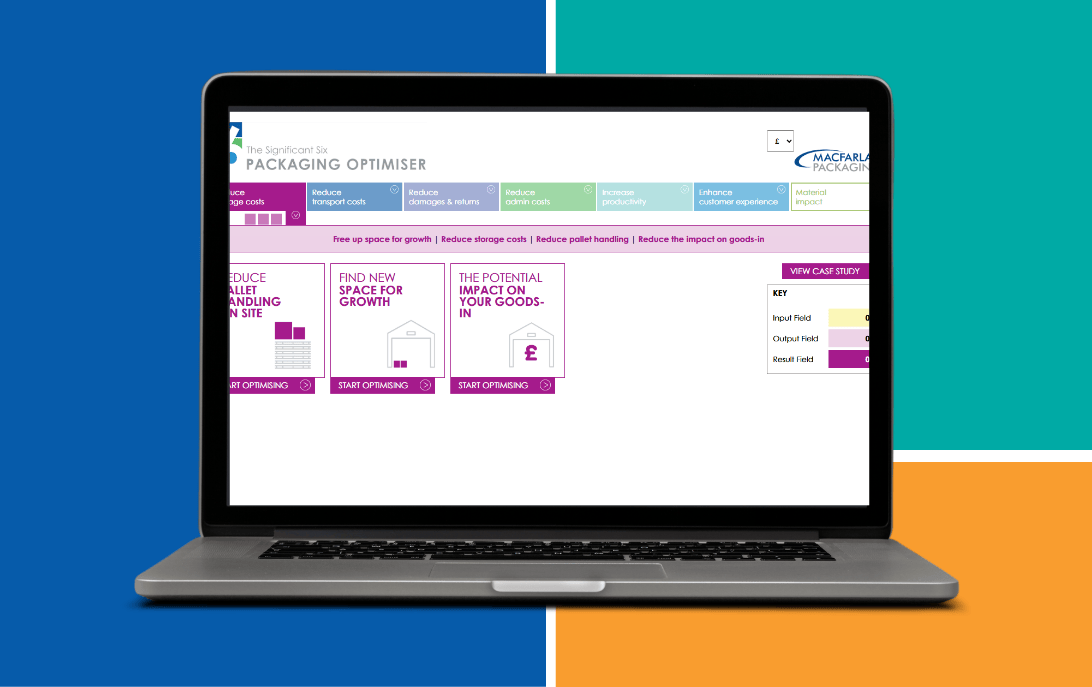

The Packaging Optimiser

Our Packaging Optimiser software can show you exactly what your packaging costs you and the environment. With CO2e illustrations as well as PRN and EPR calculators, you can see the impact of current or new packaging solutions in real-time.

Packaging Optimisation

Packaging optimisation is the key to transforming your packaging, unlocking savings, reducing your environmental impact and preparing for Extended Producer Responsibility. Using less packaging will reduce the tonnage you're putting on to the UK market. Making use of intelligent, optimised packaging design can help you achieve this while protecting your products.

State-of-the-Art Innovation Labs

90% of your packaging costs can be hiding behind the unit price you pay. And with EPR fees incoming, the packaging you use and how you use it will be more critical than ever.

Packaging Optimiser

Our Packaging Optimiser software can show you exactly what your packaging costs you and the environment. With CO2e illustrations as well as PRN and EPR calculators, you can see the impact of current or new packaging solutions in real-time.

In-House Packaging Experts

90% of your packaging costs can be hiding behind the unit price you pay. And with EPR fees incoming, the packaging you use and how you use it will be more critical than ever.

Thousands of eco-friendly products

Our Packaging Optimiser software can show you exactly what your packaging costs you and the environment. With CO2e illustrations as well as PRN and EPR calculators, you can see the impact of current or new packaging solutions in real-time.

Packaging Data Collection & Reporting

EPR reporting means that knowing the ins and outs of your packaging materials and usage is more critical than ever before.

EPR Reporting Dashboards

Developed by Macfarlane’s experts, you can access exclusive EPR reporting dashboards can give you a snapshot of your packaging use and EPR liability.

Simple e-trading

Macfarlane’s e-trading system offers click-of-a-button reporting, helping you prep for EPR data collection and PRNs.

EPR cost reduction example

A simple change saved one of our customers £6,450

A business currently ships 1,000,000 eCommerce boxes each year and uses an average of 7 air bags with each shipment. By reducing the size of their boxes to minimise the need for void fill, the company could potentially save £6,450 in their EPR costs.

Current packaging solution

Existing Box

Price – £1.00

Weight per item (KG) – 0.180

Quantity – 1,000,000

Tonnes of material used – 180,000

Proposed packaging solution

Optimised box

Price - £0.950

Weight per item – 0.150

Quantity – 1,000,000

Tonnes of material used – 150,000

Proposed packaging solution

Material reduction

Material saved annually – 30 tonnes

Material manufacturing CO₂e reduction* - 57.88 tonnes

Quantity – 0

Saving in materials costs - £50,000

*Manufacturing CO2e calculated using a drop in material weight and an increase in recycled content as follows:

Boxes - 50% recycled content to 100%

Airbags - 0% recycled content to 50% recycled content